CONDITIONING

& HANDLING

Your other fruits are perfectly conditioned — why not pears?

Pears are a climacteric fruit just like bananas, tomatoes and avocados. Ripening enhances all of these fruits in flavor and sales. Ethylene treatment is what causes a starch to sugar conversion in pears, just like bananas, which will enable customers a unique eating experience and bring them back for more.

Pears are a climacteric fruit just like bananas, tomatoes and avocados. Ripening enhances all of these fruits in flavor and sales. Ethylene treatment is what causes a starch to sugar conversion in pears, just like bananas, which will enable customers a unique eating experience and bring them back for more.

We know that many retailers have found success with increased sales and satisfied consumers from merchandising conditioned pears. Whether you condition pears in your warehouse or have your supplier condition for you before shipment, the results are equal in that consumers prefer breaking pears 3-to-1 over green fruit.

Use the quick steps below to make sure you have a ripening protocol set in your company.

For a more detailed ripening program, refer to the technical steps on back, or schedule a customized ripening training from Dennis Kihlstadius, Ripening Advisor to The California Pear Advisory Board at 310-567-8445.

The “must-have” time to condition California Bartletts: First 4 weeks of the season — typically July through mid-August.

1: Obtain ethylene-conditioned California Bartlett pears from a shipper

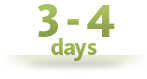

- Allow a 3-4 day lead time from order to shipping for perfect conditioning.

- Shipper will Ethylene treat pears of 100-150 ppm for 24-36 hours.

- Optimum conditioning temperatures are 64 – 66° pulp temp. This will give maximum shelf life and ensure ethylene acceptance by the fruit.

- Pears will NOT accept ethylene until the pulp temp is a minimum of 55°.

- Rapid cooling is advised after conditioning for the longest shelf life or storage time. (There is no temperature “kill-zone” with pears).

- Conditioned pears can be cooled down to 30° and brought back out to room temperature without any quality derogation or adverse effects. Temperature changes from 32-70° do not cause chilling or temperature injury.

- Temperatures at 46° or below are ideal for storage.

- First loads of the season (during the first 2 weeks of harvest) can be shipped at a warmer temp (50°) to aid ripening in route after conditioning. (First harvest pears are very high in pressure).

- Conditioned pears WILL NOT have a dramatic drop or change in pressure, until fruit is brought back to room temperature allowed to ripen. RIPENING HAPPENS AT STORE LEVEL or room temperature. There may be a 1-2 lb drop in pressure at the end of the conditioning cycle; but this in not always the case. This all depends on the time of the season and where the fruit is coming from.

- Test pressure of the pears when received at the warehouse with a penetrometer (be sure to skin the fruit first and use a small, 8mm size tip), then store as needed.

Talk with your shipper about their ripening process

How can I tell if my pears have been pre-conditioned?

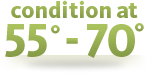

Randomly select pears from shipment and set out at room temperature, between 55-70 degrees. Pears should “break” color, turning from green to yellow and pressure of pears should begin to drop within 3 days.

2: Retail in-house conditioning

- Pears can be conditioned with bananas and there will be no adverse affect to either fruit.

- Ethylene treatment of 100-150 ppm for 24-36 hours.

- Conditioning temperatures range from 55° – 70°. When the pulp temperature of pears is over 70°, the ripening process shuts down. Always remember, as in any fruit the higher the ripening temperature, the shorter the shelf life.

- Optimum conditioning temperatures are 64 -66° pulp temp. This will give maximum shelf life and ensure ethylene acceptance by the fruit.

- Pears will NOT accept ethylene until the pulp temp is a minimum of 55°.

- Vented boxes assure the best air flow to control the ethylene absorption and temperature control.

- Temperatures at 46° or below are ideal for storage.

- First loads of the season (during the first 2 weeks of harvest) can be shipped at a warmer temp (50°) to promote ripening in route.

- Conditioned pears can be cooled down to 30° and brought back out to room temperature without any quality derogation or adverse effects. Temperature changes from 32-70° do not cause chilling or temperature injury.

- Rapid cooling is advised after conditioning for the longest shelf life or storage time.

- Conditioning is advised when the average arrival pressure is at 12lbs or above.

- Pears will not be adversely affected if conditioned twice. The pear will only accept so much ethylene and then its own processes of ripening will take over. Pears that have been conditioned already will ripen faster when more heat is applied, but keep temperature below 70 degrees.

Conditioning is just the first step in the ripening process. Ripening is meant to occur at store level NOT the warehouse or distribution center. Through proper rotation, this gives your customers a range of degrees of ripeness and also insures that pears will ripen at store level or in their homes. It brings them back for more good eating — and builds your sales at the same time!